In the realm of industrial applications, the choice of coatings and lining systems is crucial for ensuring the longevity and efficiency of equipment exposed to harsh environments. Two popular solutions are Glassflake Reinforced Novolac Vinyl Ester Coatings and Acid Proof Tile Lining Systems. Each has its own set of advantages and limitations. This article delves into a detailed comparison of these systems, focusing on their performance in chemical and temperature resistance.

1. Overview of the Systems:

1.1 Glassflake Reinforced Novolac Vinyl Ester Coatings

Glassflake Reinforced Novolac Vinyl Ester Coatings are advanced protective coatings designed to offer exceptional resistance against harsh chemicals and high temperatures. These coatings integrate glass flakes into a novolac vinyl ester resin matrix, enhancing their mechanical properties and chemical resistance.

- Composition: Glass flakes are embedded in a vinyl ester resin, which is known for its durability and resistance to aggressive chemicals.

- Applications: Commonly used in environments with severe chemical exposure, such as chemical processing plants, and in high-temperature applications.

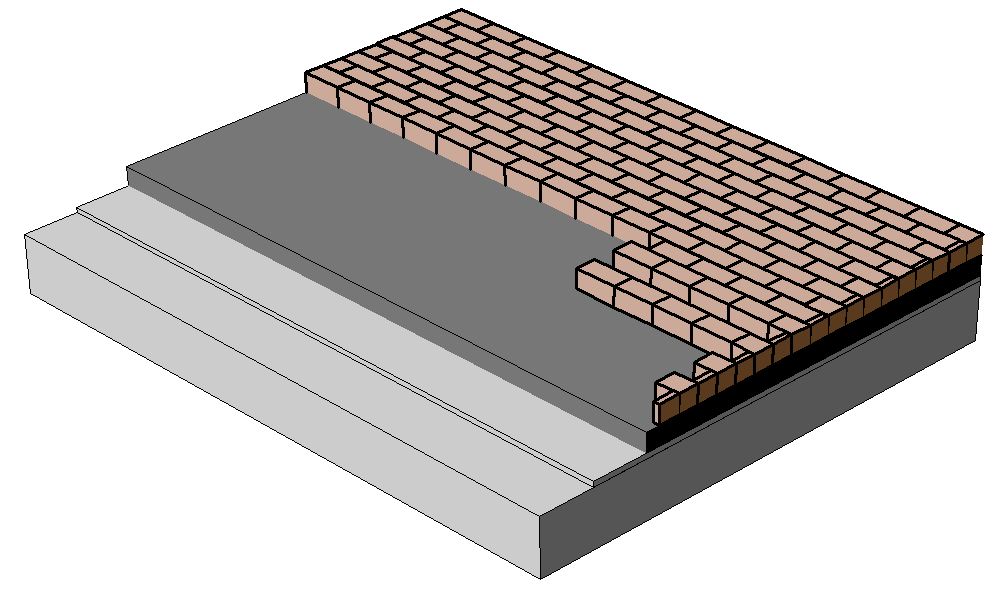

1.2 Acid Proof Tile Lining Systems

Acid Proof Tile Lining Systems consist of tiles made from materials like ceramic or porcelain that are chemically resistant and offer a protective layer for surfaces exposed to corrosive substances.

- Composition: Typically made from ceramic or porcelain with a strong acid-resistant glaze.

- Applications: Widely used in industries dealing with acids and other corrosive materials, including chemical manufacturing and wastewater treatment facilities.

2. Performance Comparison:

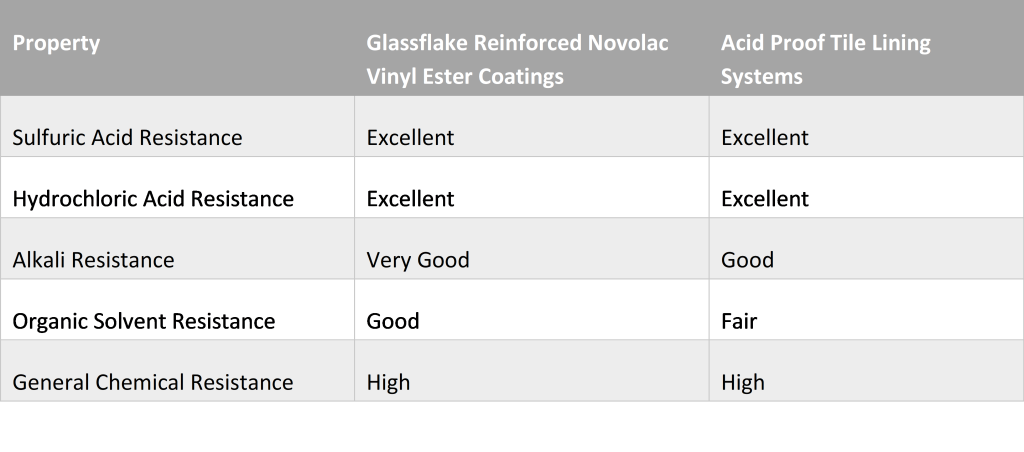

2.1 Chemical Resistance:

2.1.1. Glassflake Reinforced Novolac Vinyl Ester Coatings

- Strengths: These coatings are highly resistant to a wide range of acids, alkalis, and solvents. The glass flakes provide a barrier that prevents the ingress of chemicals and enhances the overall durability of the coating.

- Typical Resistance: Resistant to sulfuric acid, hydrochloric acid, and many organic solvents. Ideal for environments where strong acids and alkalis are prevalent.

2.1.2 Acid Proof Tile Lining Systems

- Strengths: Acid Proof Tiles are designed specifically to withstand acidic environments. Their ceramic or porcelain base is impervious to most acids, making them suitable for highly corrosive environments.

- Typical Resistance: Excellent resistance to sulfuric acid, hydrochloric acid, and other aggressive chemicals. However, resistance can vary based on the tile’s composition and glaze quality.

Table 1: Chemical Resistance Comparison.

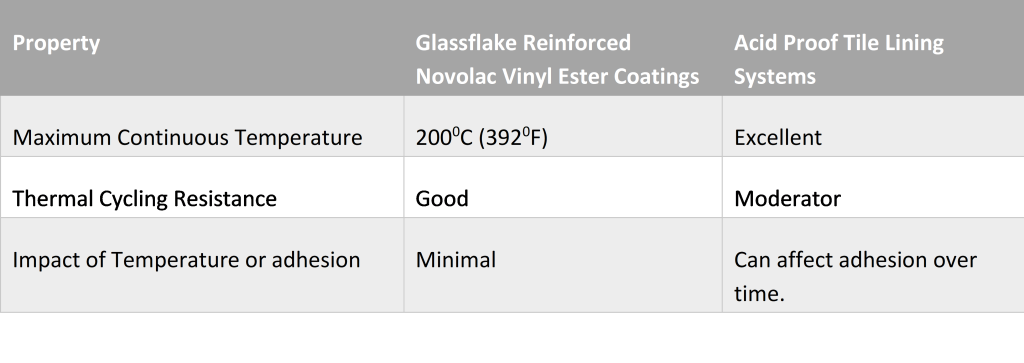

2.2. Temperature Resistance

2.2.1 Glassflake Reinforced Novolac Vinyl Ester Coatings

- Strengths: These coatings can endure high temperatures without significant degradation. The glass flakes improve thermal stability and prevent the coating from becoming brittle.

- Typical Temperature Range: Effective up to 200°C (392°F), with some formulations capable of withstanding even higher temperatures.

2.2.2 Acid Proof Tile Lining Systems

- Strengths: Acid Proof Tiles can also handle high temperatures, though their performance can be influenced by the thermal cycling and mechanical stress.

- Typical Temperature Range: Generally effective up to 300°C (572°F), but this can vary based on tile material and installation methods.

Table 2: Temperature Resistance

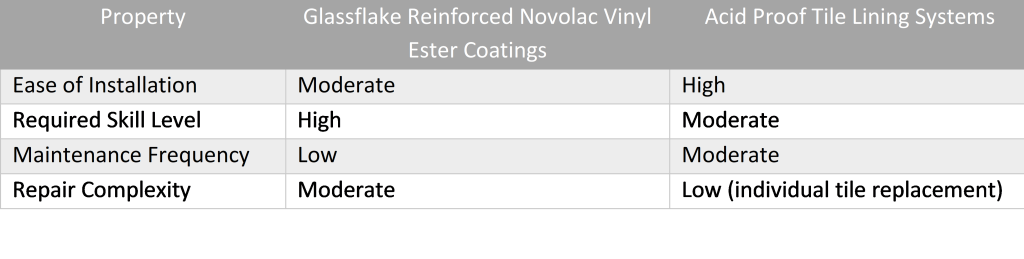

3. Installation & Maintenance

3.1 Glassflake Reinforced Novolac Vinyl Ester Coatings

- Installation: Requires proper surface preparation and application by skilled professionals. The coating process typically involves multiple layers to achieve optimal thickness and protection.

- Maintenance: Relatively low maintenance once applied, but periodic inspections are recommended to ensure the integrity of the coating.

3.2 Acid Proof Tile Lining Systems

- Installation: Involves precise tiling and grouting techniques. Proper installation is critical to prevent issues such as delamination or grout degradation.

- Maintenance: Requires regular cleaning and inspection. Tiles can be replaced individually if damaged, which can be advantageous for localized repairs.

Table 3: Installation & Maintenance Comparison

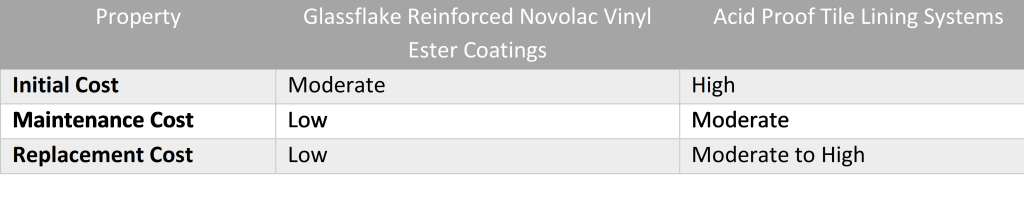

4. Cost Comparison

4.1 Glassflake Reinforced Novolac Vinyl Ester Coatings

- Initial Cost: Typically lower than the traditional Acid Proof Tile Lining System

- Long-term Cost: Lower maintenance and repair costs can further offset the initial expense over time.

4.2 Acid Proof Tile Lining Systems

- Initial Cost: Depending on the type & quality of tiles used, along with separate cost of installation – typically higher.

- Long-term Cost: Potentially higher due to maintenance and replacement needs, especially if tiles become damaged or discolored.

Table 4: Installation & Maintenance Comparison

Conclusion:

Both Glassflake Reinforced Novolac Vinyl Ester Coatings and Acid Proof Tile Lining Systems offer robust protection for industrial applications. The choice between them should be guided by the specific needs of your environment:

- Glassflake Reinforced Novolac Vinyl Ester Coatings are ideal for applications requiring high chemical and temperature resistance with lower maintenance. They offer superior protection against a wide range of chemicals and can withstand high temperatures, making them suitable for harsh and demanding environments.

- Acid Proof Tile Lining Systems are advantageous for their excellent resistance to acids and high temperatures, as well as their ease of repair and lower initial cost. They are a good choice for environments where localized damage might be a concern, and where the tile’s aesthetic and functional properties are valued.

Understanding the performance characteristics and cost implications of each system will enable engineers and decision-makers to select the best solution for their specific industrial needs.